N12Turbo.com lanyards are now available! Click here to visit the shop

Has anyone got a match

Has anyone got a match

So Here I sit, in front of the computer, pondering the incredible amount of bad luck I have had.

Pondering if I did set it a light, would a strange fireball shoot out and hit me.

So, I thought I was close, a week or two and I'll rego it.

everything is about done.

Except for that smoking problem, and as all the other stuff is finished, I turned to looking at it,

After reading all the stuff about ET's smoking, I thought it wont be that bad to fix.

but when I pulled the turbo and manifold off, so I could have a better look, I had a bad feeling, 2 ports where wet with oil, and 2 where dry.

Oh no, pulled the sparks out, yeap, wet,

OK what to do, so I when to my local mechanic and borrowed his compression tester, did a check, both wet and dry, and found one of the cylinders has almost no compression ....

So what to do...

I dont feel like bebuilding it,

I cant afford to pay someone to do the job.

I thought, just put a E15 N/A back in and leave it for a bit, drive it,

and rebuild the E15T later with time and do a good job,

or maybe if I can find a CA18s, I would consider dropping it in....

I dont know, Just a little tired of it now...

Feeling old and over it......

I'll probably rip the head off in the next few days and see whats up.

maybe just plod along and rebuilt it......

ANy suggestions????

FYI

Cyl .1. .2. .3. .4.

Dry 120 20 110 110

Wet 160 20 160 155

.

.

Pondering if I did set it a light, would a strange fireball shoot out and hit me.

So, I thought I was close, a week or two and I'll rego it.

everything is about done.

Except for that smoking problem, and as all the other stuff is finished, I turned to looking at it,

After reading all the stuff about ET's smoking, I thought it wont be that bad to fix.

but when I pulled the turbo and manifold off, so I could have a better look, I had a bad feeling, 2 ports where wet with oil, and 2 where dry.

Oh no, pulled the sparks out, yeap, wet,

OK what to do, so I when to my local mechanic and borrowed his compression tester, did a check, both wet and dry, and found one of the cylinders has almost no compression ....

So what to do...

I dont feel like bebuilding it,

I cant afford to pay someone to do the job.

I thought, just put a E15 N/A back in and leave it for a bit, drive it,

and rebuild the E15T later with time and do a good job,

or maybe if I can find a CA18s, I would consider dropping it in....

I dont know, Just a little tired of it now...

Feeling old and over it......

I'll probably rip the head off in the next few days and see whats up.

maybe just plod along and rebuilt it......

ANy suggestions????

FYI

Cyl .1. .2. .3. .4.

Dry 120 20 110 110

Wet 160 20 160 155

.

.

yes if you set it alight a fireball will get you for sure

you and the duck have come to far mate

take the head off and have a look it mite only be rings if so not that bad as long as the bore is still stock size only needing a hone and a new set if no good put the n/a back in get it on the road for a bit and enjoy all that hard work you been putting in over the last afew years

thats what I would do and by the sound of your thread thats what you're wanting to hear yes

hang in there mate you and the duck have come to far to throw in the towel now mate

zoomzoom

you and the duck have come to far mate

take the head off and have a look it mite only be rings if so not that bad as long as the bore is still stock size only needing a hone and a new set if no good put the n/a back in get it on the road for a bit and enjoy all that hard work you been putting in over the last afew years

thats what I would do and by the sound of your thread thats what you're wanting to hear yes

hang in there mate you and the duck have come to far to throw in the towel now mate

zoomzoom

tits'n' wheels gotta love'em

After reading the post for the 3 time, I finally noticed the comp numbers for #2. Definitely check your valve clearance. You don't get a compression loss like that with worn rings, cracked ringlands or blown gasket! If you don't have a compression gauge, I'd be listening to where the combustion gasses are going. Trust me, you will hear them. Whip out plugs 1 3 and 4, get a friend to wind the motor over by hand (ratchet on the crank pully) and listen to wether the leak is from the inlet valve (air leak noise in the inlet) or the exhaust valve (if you whip out the O2 you will hear it through here) or, into the crankcase, which will show as air noise in the oil filler.

Once you have found where the leak is, set you valve clearance on #2 and do the whole thing again. If there is a noticeable change in the 'leak', you may well have dodged a bullet.

I would avoid doing the valve clearance on the other cylinders till you can identify what is happening with #2.

That aside, as Callum has suggested, get hold of a NA E15, bolt the good bits to it, run the thing on 95 or better,and boost around 10psi till you can do a proper standard rebuild on your existing donk. A complete running E15 shouldn't cost you $100 if you can find one.

Damo

Once you have found where the leak is, set you valve clearance on #2 and do the whole thing again. If there is a noticeable change in the 'leak', you may well have dodged a bullet.

I would avoid doing the valve clearance on the other cylinders till you can identify what is happening with #2.

That aside, as Callum has suggested, get hold of a NA E15, bolt the good bits to it, run the thing on 95 or better,and boost around 10psi till you can do a proper standard rebuild on your existing donk. A complete running E15 shouldn't cost you $100 if you can find one.

Damo

Do humanity a favor, use your brain and fight the forces of WOO WOO!

http://www.youtube.com/watch?v=G1mrbxhWU5Y

http://www.youtube.com/watch?v=G1mrbxhWU5Y

I wouldn't have thought this was from rings unless they are missing entirely. I'd be inclined to pull the Rocker cover off and make sure there is a full range of motion on the valves, and that the rockers are set to the correct specs.

Every time I've had issues with piston rings, a wet comp-test always gives at least a slightly higher compression value.

Other than a valve issue, it could be a hole in the piston, but then you should be pressurising the hell out of your oil-pan, and blowing oil out the dipstick hole (and the dipstick too probably).

Don't give in yet, it could be something as simple as rockers not allowing valves to close fully, but not holding them open enough to hit the top of the piston..

Cheers

Jay

Every time I've had issues with piston rings, a wet comp-test always gives at least a slightly higher compression value.

Other than a valve issue, it could be a hole in the piston, but then you should be pressurising the hell out of your oil-pan, and blowing oil out the dipstick hole (and the dipstick too probably).

Don't give in yet, it could be something as simple as rockers not allowing valves to close fully, but not holding them open enough to hit the top of the piston..

Cheers

Jay

Have not had any time to really work on it....

But

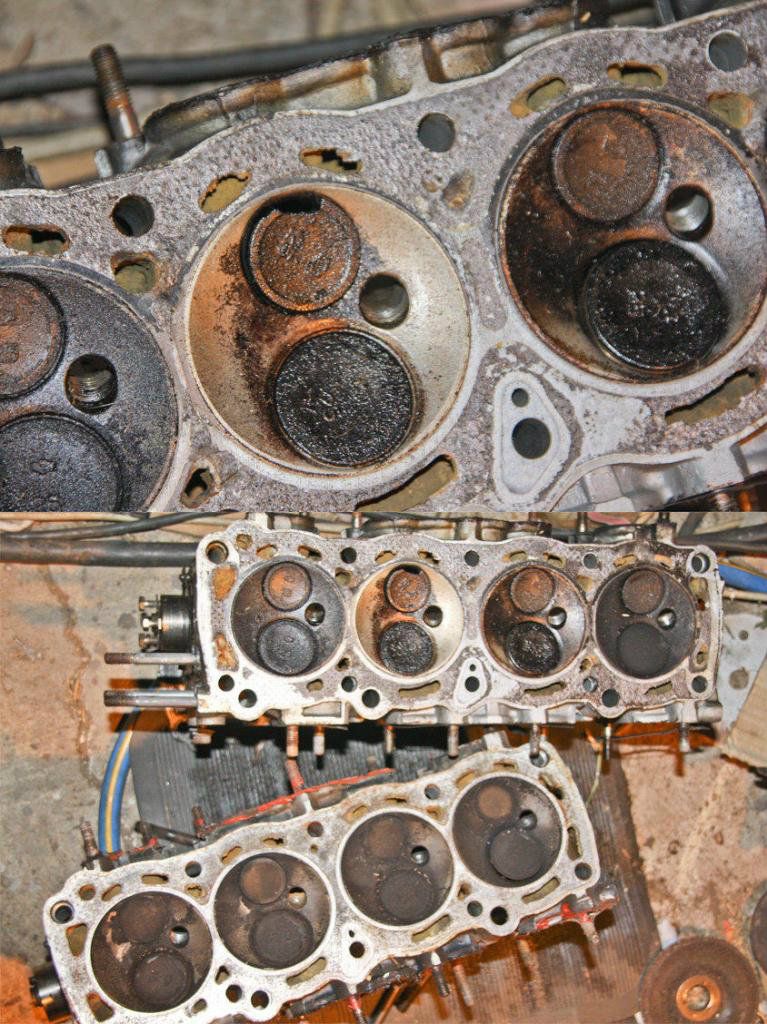

I did rip the head off... and found.....

Not a hole in the piston....

but a broken valve. Nice little piece from it missing.

The bore looks OK.

I will post some photos when I get time...

But I have 2 questions...

First... If you guys remember the whole issue was that it was blowing smoke.

First I was told it was a blown turbo.. but it was not that...

Then I found one piston with low compression...

The question is... could this cracked valve cause the smoke problem...

I can see how it would drop compression... there is a big gap that the valve does not block...

But I cant see how that would cause the smoking ?????????????

Second question... Once I get the head repaired...

Is there any way to check if there is anything wrong with the piston rings

other than pulling them out and changing them ?????

(If I can get a way without pulling the bottom end apart, that would be great)

Of course once I put the head back on, I'll do another compression test.

But if I find anything at that point... I would really get a match...

But

I did rip the head off... and found.....

Not a hole in the piston....

but a broken valve. Nice little piece from it missing.

The bore looks OK.

I will post some photos when I get time...

But I have 2 questions...

First... If you guys remember the whole issue was that it was blowing smoke.

First I was told it was a blown turbo.. but it was not that...

Then I found one piston with low compression...

The question is... could this cracked valve cause the smoke problem...

I can see how it would drop compression... there is a big gap that the valve does not block...

But I cant see how that would cause the smoking ?????????????

Second question... Once I get the head repaired...

Is there any way to check if there is anything wrong with the piston rings

other than pulling them out and changing them ?????

(If I can get a way without pulling the bottom end apart, that would be great)

Of course once I put the head back on, I'll do another compression test.

But if I find anything at that point... I would really get a match...

- dexi_styles

- Posts: 1227

- Joined: Fri Aug 25, 2006 1:49 pm

- Location: South Brisbane

Which valve...? Inlet or outlet

If it's the outlet I'd say it's a cause. I'm nit sure what any dramas a cracked inlet would do.

Dex

If it's the outlet I'd say it's a cause. I'm nit sure what any dramas a cracked inlet would do.

Dex

http://forum.n12turbo.com/viewtopic.php?t=446 Benny's Old Dog....

Bringing New life to the Young Dog...

http://forum.n12turbo.com/viewtopic.php?t=348

Bringing New life to the Young Dog...

http://forum.n12turbo.com/viewtopic.php?t=348

Well.... I left it for a few weeks as I finished up some wedding photos.

And now I am ready to fix the bloody thing.

So tomorrow I'm taking the head down to a shop to see what they say.

also I will find a place to weld the manifold.

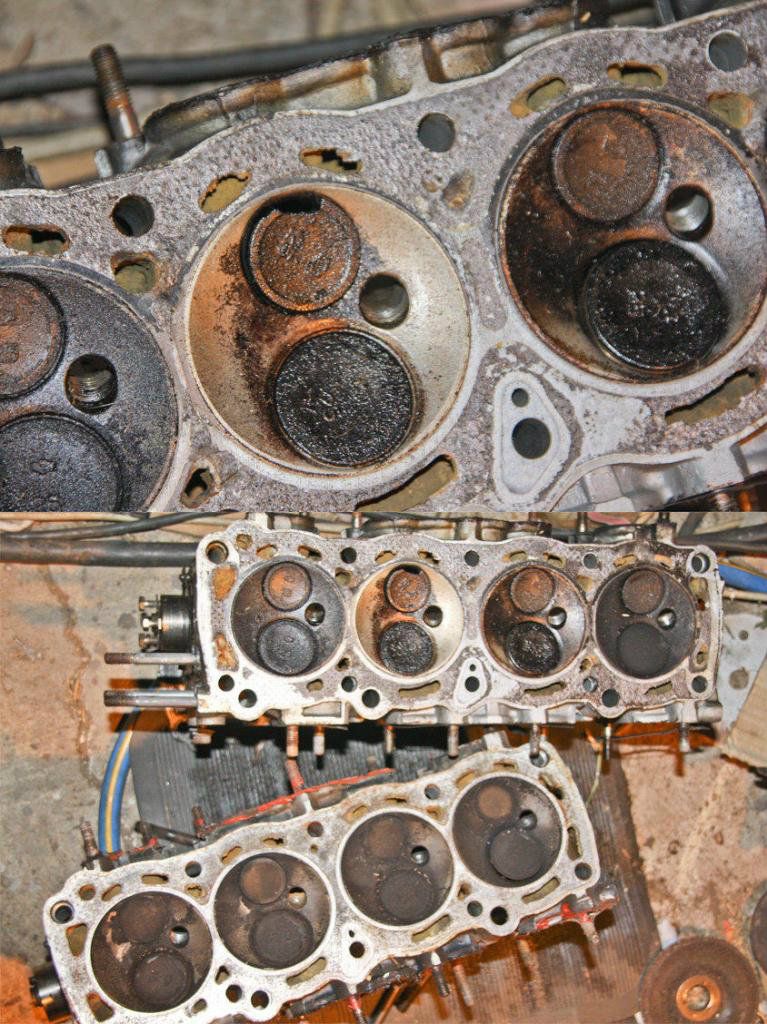

I ripped the head of the spare motor and notice that the heads pistons are different.

The spare has dished piston heads and the one I am using there got a odd shape.

I Would love to know something about the piston heads if anyone can enlighten me.

Also any more thoughts on the 2 Questions

And now I am ready to fix the bloody thing.

So tomorrow I'm taking the head down to a shop to see what they say.

also I will find a place to weld the manifold.

I ripped the head of the spare motor and notice that the heads pistons are different.

The spare has dished piston heads and the one I am using there got a odd shape.

I Would love to know something about the piston heads if anyone can enlighten me.

Also any more thoughts on the 2 Questions

- tassuperkart

- Administrator

- Posts: 5578

- Joined: Wed Jul 05, 2006 8:39 pm

- Location: Southern Tasmania

- Contact:

Oh yeah, Its burnt, fried, and stayed.

Well... With the headache its given me. It should also be exploded then ground into a fine power LOL

Pretty sure its the reason for the compression at 20.

Getting that head reoc'd this week, $200 for the lot including Pressure testing.

At least I wount have any valve stem seal or timing belt problems in the near future.

That head looks like its had some porting work done as well (before).

Hey E,

Can you shed some of your wisdom on the questions I asked earlier.

Re:- could this valve of caused the smoke... and is there any way to check the

bottom end without ripping it apart.

I am very stress that after I put the head back on I find the the oil rings are gone.

Right now its just too much for me to rip the rest apart if it does not need it.

Thanks

I've put the match down... For now...

But I am going to get the kerosene out if these problems persist. LOL

.

Well... With the headache its given me. It should also be exploded then ground into a fine power LOL

Pretty sure its the reason for the compression at 20.

Getting that head reoc'd this week, $200 for the lot including Pressure testing.

At least I wount have any valve stem seal or timing belt problems in the near future.

That head looks like its had some porting work done as well (before).

Hey E,

Can you shed some of your wisdom on the questions I asked earlier.

Re:- could this valve of caused the smoke... and is there any way to check the

bottom end without ripping it apart.

I am very stress that after I put the head back on I find the the oil rings are gone.

Right now its just too much for me to rip the rest apart if it does not need it.

Thanks

I've put the match down... For now...

But I am going to get the kerosene out if these problems persist. LOL

.

- tassuperkart

- Administrator

- Posts: 5578

- Joined: Wed Jul 05, 2006 8:39 pm

- Location: Southern Tasmania

- Contact:

Its a hard one this.

But no, the burnt valve was a result of leanness/detonation.

Oil rings allowing that much oil in there....I dunno. from what I cann see, the bores look in reasonable order.

However the piston tops are suspiciously clean...................

There is a shitload of oil in those chambers which leads me to think you may have something wrong with your breather setup.

Thhis is a hard one.

Oracle

But no, the burnt valve was a result of leanness/detonation.

Oil rings allowing that much oil in there....I dunno. from what I cann see, the bores look in reasonable order.

However the piston tops are suspiciously clean...................

There is a shitload of oil in those chambers which leads me to think you may have something wrong with your breather setup.

Thhis is a hard one.

Oracle

Forcd4 wrote:Oh fuk no dude it's you a again, the oracle.

Thanks E

Yeah, there is a lot of oil,

I was thinking that that was because of the wet compression test.

I went down the the head shop to drop off the valve stem seals

and had a look at the head stripped down....

The head has had plenty of work, Port polish, Double valve spring, ect.

What I found out was that the burnt valve's "steam seal" was totally destroyed.

The Guy said this would definitely of let loads of oil through causing lots of smoke.

But with my luck, I just cant believe it,

I'll throw it together and still blow smoke.

my luck

I also got the exhaust manifold welded,

took it to some real welding experts and they done a nice job,

done properly, including letting it cool down in a sand bath......

and it only cost $100.

Spiff, if only you contacted me one day earlier, I would of jumped at it.

but I already made the commitment, but next week after its done,

I'll know the money situation and may take it anyway,

Also I am desperately looking for a good starter motor, if you got one.

Yeah, there is a lot of oil,

I was thinking that that was because of the wet compression test.

I went down the the head shop to drop off the valve stem seals

and had a look at the head stripped down....

The head has had plenty of work, Port polish, Double valve spring, ect.

What I found out was that the burnt valve's "steam seal" was totally destroyed.

The Guy said this would definitely of let loads of oil through causing lots of smoke.

But with my luck, I just cant believe it,

I'll throw it together and still blow smoke.

my luck

I also got the exhaust manifold welded,

took it to some real welding experts and they done a nice job,

done properly, including letting it cool down in a sand bath......

and it only cost $100.

Spiff, if only you contacted me one day earlier, I would of jumped at it.

but I already made the commitment, but next week after its done,

I'll know the money situation and may take it anyway,

Also I am desperately looking for a good starter motor, if you got one.