N12Turbo.com lanyards are now available! Click here to visit the shop

want ideas on how to build strong enough box

want ideas on how to build strong enough box

As tittle suggests looking for any1's input on how i can build a strong enough box or where to get 1. Car is getting alot of work done and will be hopefully putting out alot of power. So now just need to make sure the box will hold out. So any1 got any suggestions would be much appreciated. thanks

- Ben Hewitson

- Posts: 1136

- Joined: Tue Aug 08, 2006 9:19 am

- Location: Adelaide, SA.

- Contact:

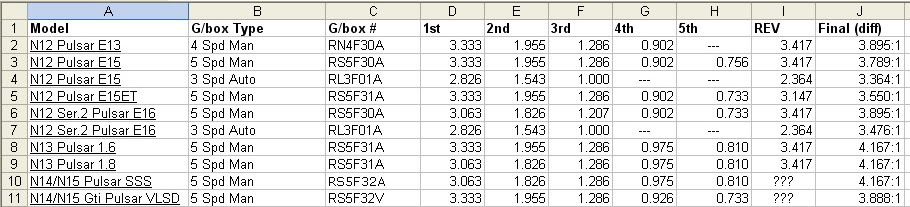

first off. You can run N13 internals. Read up on Nissanexa.com for details on that.

http://forum.nissanexa.com/showthread.php?t=20968

this will give you a 4:1 (lower) final drive ratio which tends to shorten up the gears and also unloads th egearbox a little as its got lower gearing. tends to survive the torque easier.. or you can take the final drive from an N/A E15 to get about 3.8:1..

Also the N13 internals are also strong enough for the 4wd CA18DET powered cars so they should do alright in an E15.. although most people dont realise a worked ET will make about as much torque as an STi.. and thats mad for our little gearboxes.. its not cause they are weak, its just we usually throw a bucket load of torque at them.

and other alternative is to get custom stuff mage up ($$bling$$)

and finally i would recomend not running a ceramic puck style clutch.. This is just my point of view but we we used to use the ceramic clutches we always had CV joint and gearbox problems. the clutch was so harsh that it just smashed the driveline.. we decided to run very HD clutch assemblies (grabbed one from my Datto 1600 which was the same as E15.. lol) and ran decent quality Organic plates. we found that, yes they would slip after time but they were easier to use on the street and a $80 clutch plate was cheaper than another driveshaft or engine rebuild. an organic clutch plate will definately 'cushion' the driveline during changes and sticky bitumen.

http://forum.nissanexa.com/showthread.php?t=20968

this will give you a 4:1 (lower) final drive ratio which tends to shorten up the gears and also unloads th egearbox a little as its got lower gearing. tends to survive the torque easier.. or you can take the final drive from an N/A E15 to get about 3.8:1..

Also the N13 internals are also strong enough for the 4wd CA18DET powered cars so they should do alright in an E15.. although most people dont realise a worked ET will make about as much torque as an STi.. and thats mad for our little gearboxes.. its not cause they are weak, its just we usually throw a bucket load of torque at them.

and other alternative is to get custom stuff mage up ($$bling$$)

and finally i would recomend not running a ceramic puck style clutch.. This is just my point of view but we we used to use the ceramic clutches we always had CV joint and gearbox problems. the clutch was so harsh that it just smashed the driveline.. we decided to run very HD clutch assemblies (grabbed one from my Datto 1600 which was the same as E15.. lol) and ran decent quality Organic plates. we found that, yes they would slip after time but they were easier to use on the street and a $80 clutch plate was cheaper than another driveshaft or engine rebuild. an organic clutch plate will definately 'cushion' the driveline during changes and sticky bitumen.

Last edited by Ben Hewitson on Wed Aug 23, 2006 12:38 pm, edited 3 times in total.

- Ben Hewitson

- Posts: 1136

- Joined: Tue Aug 08, 2006 9:19 am

- Location: Adelaide, SA.

- Contact:

- Paul Smith

- Posts: 575

- Joined: Thu Aug 03, 2006 4:55 pm

- Location: Brisbane

well you can throw the custom made dog box idea out unless u can get 5 or more people to buy them and at $3800 for helical cut and 5k for a dog box there isnt to many people that wanna spend that money. trust me i asked abotu a month ago cause my box was fuked. so i just got it rebuilt and got the spider gears shimed up like a mofo so it acts kinda like a lsd but i think they have worn out and giving me a noise.but i dunno

- tassuperkart

- Administrator

- Posts: 5578

- Joined: Wed Jul 05, 2006 8:39 pm

- Location: Southern Tasmania

- Contact:

Another point to ponder is that the box internals are only as tough as the cases they are living in and the design of the gearcases does not look too tough in my opinion.

Unless you are prepared to adapt a different brand of gearbox altogether, which altho quite feasable, is a very big (read expensive) job, then your stuck with adding some somewhat tougher n13 gearsets, a lower diff and little else.

Adding an organic clutch plate is a very wise decision and as Ben has pointed out, makes for much gentler clutch takeups and easier driving.

I would avoid using a puck clutch plate under all circumstances. Bastards of things in my view. Id rather spend my money on an expensive twin plate organic clutch setup that i can drive around than fuck about with a button clutch plate.

Organic plates tend to only suffer on repeated launches and if you have to drive this way then ............... well, you get the idea.

L8tr

E

Unless you are prepared to adapt a different brand of gearbox altogether, which altho quite feasable, is a very big (read expensive) job, then your stuck with adding some somewhat tougher n13 gearsets, a lower diff and little else.

Adding an organic clutch plate is a very wise decision and as Ben has pointed out, makes for much gentler clutch takeups and easier driving.

I would avoid using a puck clutch plate under all circumstances. Bastards of things in my view. Id rather spend my money on an expensive twin plate organic clutch setup that i can drive around than fuck about with a button clutch plate.

Organic plates tend to only suffer on repeated launches and if you have to drive this way then ............... well, you get the idea.

L8tr

E

Forcd4 wrote:Oh fuk no dude it's you a again, the oracle.

Gearbox

The cheap option here is a N12 gearbox with N13 internals. These have proven themselves to be relatively strong in racing.

If you have a decent budget, you might want to try and get an engineering place to retro fit a different gearbox e.g 4AGZE to an E15ET motor. This does require extensive machining and facrication work but in the long run you have a stronger then standard gearbox for you.

If money isn't a problem, you can get say PAR to do a custom gear set to fit in the standard box. This way you can get any gear ratio you want including final drive.

Some food for thought

Cameron

If you have a decent budget, you might want to try and get an engineering place to retro fit a different gearbox e.g 4AGZE to an E15ET motor. This does require extensive machining and facrication work but in the long run you have a stronger then standard gearbox for you.

If money isn't a problem, you can get say PAR to do a custom gear set to fit in the standard box. This way you can get any gear ratio you want including final drive.

Some food for thought

Cameron

- Ben Hewitson

- Posts: 1136

- Joined: Tue Aug 08, 2006 9:19 am

- Location: Adelaide, SA.

- Contact:

thats correct. N13 stuff probably isn't any stronger. but the lower ratio diff definately unwinds the box. look at lou's exa.. broke like 10 boxes then built an N13 internaled one up.. bingo..

also. dont go custom or dog engagement. apart from it being to expensive its really only as good as the case.. as its been mentioned already.

the strongest internals mean nothing when then main shaft bearing (bellhousing side) is incased in 6mm of alloy... not a lot..

you may not break a gear but there is nothing stopping it ripping the casing apart.. then all your expensive gears will spill out on the track or the road like some sort of robotic entrails and gore.. not cool..

also look into the oldschool ford sierra gearboxes. i believe they can be made to fit the N12. talk2 pulsar parts in SA.. someone said they had one.

also look over at nissanexa.com and search my posts (2700 of them i'm sorry) for gearbox related stuff.. we had like a 50 page discussion on this topic and i beleive we covered it well there.. i'll try to cut and paste it in here later if i can.

also. dont go custom or dog engagement. apart from it being to expensive its really only as good as the case.. as its been mentioned already.

the strongest internals mean nothing when then main shaft bearing (bellhousing side) is incased in 6mm of alloy... not a lot..

you may not break a gear but there is nothing stopping it ripping the casing apart.. then all your expensive gears will spill out on the track or the road like some sort of robotic entrails and gore.. not cool..

also look into the oldschool ford sierra gearboxes. i believe they can be made to fit the N12. talk2 pulsar parts in SA.. someone said they had one.

also look over at nissanexa.com and search my posts (2700 of them i'm sorry) for gearbox related stuff.. we had like a 50 page discussion on this topic and i beleive we covered it well there.. i'll try to cut and paste it in here later if i can.

- tassuperkart

- Administrator

- Posts: 5578

- Joined: Wed Jul 05, 2006 8:39 pm

- Location: Southern Tasmania

- Contact:

Ahhhhh no M8, it means MORE power ATW's.

Lower diff ratio = higher torque multiplication.

The ET is overdiffed to buggery in the first place and the overdriven 4th and 5th gears along with the stock wheels are very tall for a pissy litte 1.5L even with a huffer.

Even worse whn the dudes are adding 17's and bigger!

My turboed GX has the 3.7 diff with 13" x 60 cheesecutters and lifts off well!

Itll eat an ET alive off the mark

Id drop in the 4.1 diff as a matter of course if i was even half serious about performance.

Dont even think about running out of revs on the highway.

My old 1600 Capri turbo had a four eleven esky panelvan diff and i wanted something around 4.5 with the 13" wheels to get the thing to really sing!

L8tr

E

Lower diff ratio = higher torque multiplication.

The ET is overdiffed to buggery in the first place and the overdriven 4th and 5th gears along with the stock wheels are very tall for a pissy litte 1.5L even with a huffer.

Even worse whn the dudes are adding 17's and bigger!

My turboed GX has the 3.7 diff with 13" x 60 cheesecutters and lifts off well!

Itll eat an ET alive off the mark

Id drop in the 4.1 diff as a matter of course if i was even half serious about performance.

Dont even think about running out of revs on the highway.

My old 1600 Capri turbo had a four eleven esky panelvan diff and i wanted something around 4.5 with the 13" wheels to get the thing to really sing!

L8tr

E

Forcd4 wrote:Oh fuk no dude it's you a again, the oracle.

- tassuperkart

- Administrator

- Posts: 5578

- Joined: Wed Jul 05, 2006 8:39 pm

- Location: Southern Tasmania

- Contact:

it nearly always spun twins thats the thing it waas more likely to spin twins after the brass button went it 17 rims were the go it kept wheelspin under control BUT the engine asked for a rest i have a video on my site showing how slow it accelerated with very low compression  sounded impressive but really didnt go well it did go it went up in smoke hahahaha

sounded impressive but really didnt go well it did go it went up in smoke hahahaha

all that was with only 105kw atw cant wait til this engine goes the turbos is twice the size hehehe i would say a PGD is on the cards ill run with n12 gearset before changing

all that was with only 105kw atw cant wait til this engine goes the turbos is twice the size hehehe i would say a PGD is on the cards ill run with n12 gearset before changing