I have finished working on the T25G and will hopefully be fitting it into the car in the next two weeks...

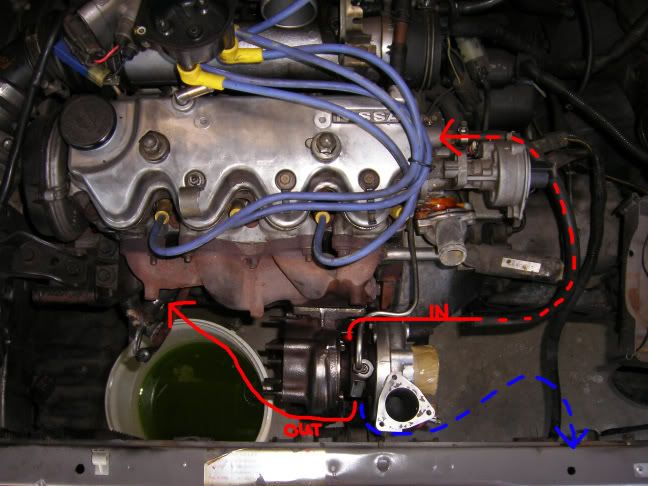

I'll take you through fitting and getting the T25G setup on the E15ET motor.. including water cooling, oil supply and exhaust..

ok Firstly, this is the original turbo from a late model SR20DET.. most likely a S14 balck top motor. pre 1992 as it doesn't have the 2 bolt snout...

This turbo has the Following A/R's.. Compressor A/R 0.80 and Turbine A/R 0.64.. This is fine for the 2L twin cam motor but a little heafty for the little 1.5L...

Ok the second step is to remove the Turbine cover and rotate the turbo... I had a T25 (standard model) lying around and decided to swap off the Turbine Covers thus removing the Lag ascociated with the T25G on the E15 and replacing it with the tighter A/R 0.48 from a T25. This should give me spool up like a T25 with the massive wack from the 0.80 A/R compressor...!!! cant wait..

The difference is not the turbine size or the exhaust size, its the distace between the edge of the turbine and the housing.. the .48 has only a slim gap so most if not all of the exhaust gas has to pass through the compressor..

As some of you heard i damaged 4 turbine blades by dropping the turbo...! D'oh!... i straightened them with plyers and took it to ATS in Adelaide and Bill put it on the dynamic balancer and gave me the all clear for balance, oil and water sealing.. Turbo is top notch.!! go Ben..

This is a box of spare bits i have... Many thanks to Paul (BOOSTIN) for the turbine cover.. (i'll give you the bits back soon)

This is a T28BB core on the left, Pauls T25 in the middle and my old U11 T25 on the right.. note the old cores had a screw type oil drain and are a direct bolt on from the old T02's...

The comp cover in front it the 0.60 A/R T25BB and the turbine covers in the bottom are .64 T25G and my broken T25..

stay tuned...

.

.  .

.